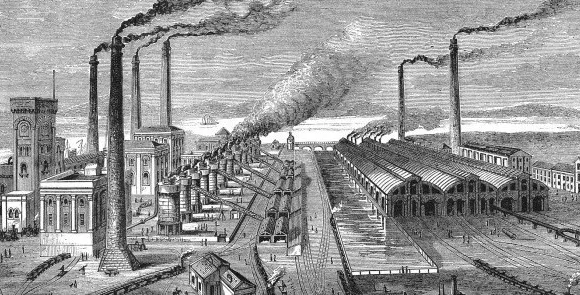

In the early 1700s, Great Britain reached a new milestone. After its people had invested plenty of research and resources into food production, their agricultural revolution resulted in a food surplus. As a result, the Brits needed to find innovative ways to process their swelling harvest. At the same time, Britain had massive supplies of cheap coal. And since there was a lot of food, the population grew fast. When Brits began to explore these factors, they moved from an agrarian and handicraft economy to one dominated by industry and machine manufacturing. That Industrial Revolution, which started in Great Britain, spread quickly to other countries globally. Today, some of those countries have overtaken the United Kingdom as it ranks 9th among the world’s top manufacturers.

Africa was not part of that movement. Meanwhile, studies of Asian economic success stories — from Japan, South Korea, Taiwan, Singapore, China, Malaysia and, more recently, Vietnam and Bangladesh — have found that building a competitive manufacturing sector is the fastest way for a country to climb the productivity ladder and raise living standards. Some argue that colonialism played a significant role in stalling Africa’s advancement. But that doesn’t hold as an excuse. India contributes nearly twice as much as Britain (their colonial masters) to global manufacturing. But that’s not the point.

Today, an African country seems to have entered its ‘Industrial Revolution.’ According to Africa Facts Zone, Egypt has built up to 10,000 factories in the last seven years. For context, as of 1813, there were only 2400 factories in Britain, even though the Industrial Revolution started many decades before. But by 1850, the number had jumped to 250,000.

Egypt’s economy is now Africa’s second-largest. As of 2020, it reached $363.1 billion in nominal GDP, closing in on Nigeria’s $432 billion despite having half the latter’s population. According to Nevine Gamea, Egypt’s Minister of Trade and Industry, the sector grew 6.5 per cent in 2021, contributing 17 per cent to the nation’s GDP. That’s almost twice as much as what manufacturing contributes to Nigeria (9 per cent). There’s no doubt that Egypt’s manufacturing sector is prospering. But can other African countries replicate its success?

Different times, different climes

Egypt’s industrial boom is no sudden emergence. It has a nearly two-century-long backstory with several failures. But importantly, the country’s journey has been unique compared to its neighbours. For instance, a researcher described Egypt at the start of World War I as “far ahead in economic development as measured by agricultural output, foreign trade, transport facilities, and, to a lesser degree, employment in the industry.” When it first started working towards an industrial economy, Egypt already had transport systems that aided that movement. That wasn’t the case in many African countries. Even to date, many suffer from glitchy transport networks.

However, the most notable difference between Egypt and others is that its industrial movement was government-initiated. It wasn’t just about private individuals who sought to build businesses. So the private builders did not have the burden of creating the environment for manufacturing to thrive. That’s not what happens in most other climes.

Nigeria is the world’s 12th largest instant noodle market, where locals consume 1.76 billion servings of noodles annually. However, it took a tooth-nail battle to reach this state. Indomie, the country’s leading brand, decided to start local production in 1995. But the company had to provide its own infrastructure. Electricity, water supply, security and even roads were all part of their starting budget. The costs ran so high that it was like creating a mini-state. That’s the same problem most people face when they want to start factories. It’s expensive enough to run a factory. Providing basic amenities for that factory makes it ridiculously risky, especially when you’re still paying tax on your gains.

Replicating Egypt’s success is not easy for most countries because they have problems deeper than a lack of factories. So, although Africa has enough unemployed youth ready to work in factories, the continent is not ready for proper industrialisation.

Ironing out the irony

The irony is that Africa has a reputation as an emerging tech hub. Countries like Kenya, Nigeria, Egypt and South Africa have seen a spike in the number of tech startups and demand for tech skills. The continent is aligning with the growing knowledge economy. But its shortcomings in manufacturing continue to catch up with it. For instance, as of 2020, Nigeria ranked as the third-highest destination of used cars from the US, behind Mexico and the United Arab Emirates. But it’s not among the top destinations for used laptops. There are many possible reasons for this, one being the wide earning gap among different social classes. Most Nigerians, who spend most of their earnings on food, cannot afford laptops. It’s the same with smartphones. A 2021 report by Zimbabwe’s Econet Wireless showed that the cost of phones— not necessarily data— keeps millions of Africans offline.

Most countries seem satisfied exporting their agricultural produce and natural resources. But maybe the spiking interest in tech is a pointer that Africa needs to take manufacturing more seriously. It won’t be easy to reach its potential in the knowledge economy when it can’t produce the requisite tools.